Just-in-Time Inventory Management

BOOK A FREE DEMO

The Just-In-Time (JIT) inventory management strategy is one in which a business maintains only the bare minimum quantity of merchandise necessary to fulfil the demands of the present market. Just-in-time inventory management aims to synchronise production with consumer demand to eliminate wastage, cut expenses, and increase productivity.

The strategy calls for meticulous planning, accurate projections, and close collaboration between all of the organisations involved in inventory management. The organisation needs a proper and prompt supply chain system to guarantee that the materials will be delivered precisely when production requires them. Using this strategy to manage inventory can help businesses function more effectively, reduce expenses associated with handling inventory, and prevent the dangers of overstocking or understocking.

What is Just In Time (JIT) inventory management?

JIT inventory management is a strategic approach to inventory management in which materials or supplies are ordered based on client requests rather than relying primarily on projections and keeping surplus inventory until it is purchased.

JIT inventory management (lean inventory management) has just enough supplies and resources to fulfil incoming requests — with as little storage as possible.

JIT as a strategy was first developed by Toyota in the 1930s. SInce then, it has been adopted by many businesses worldwide. Adopting JIT inventory management strategies may be helpful even for tiny, growing firms.

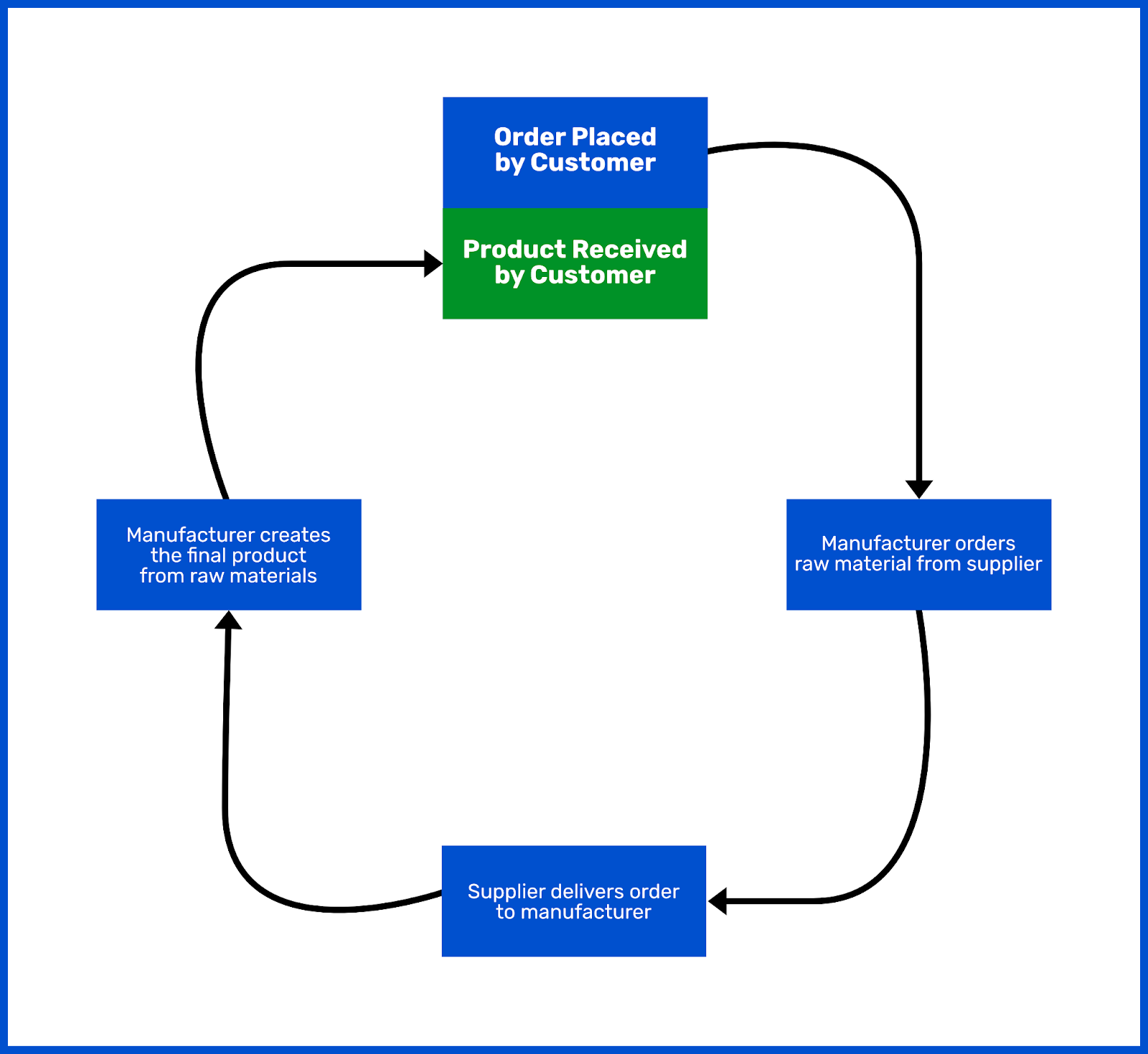

How does JIT work?

First, let’s go through JIT inventory management for a single purchase instance:

Your firm receives a client order which needs more inventory.

Next, order the materials, resources, and goods required to fulfil your customer’s purchase.

You get the supplies and immediately begin processing the order for distribution, ensuring that the items spend less time in storage.

It might appear to be straightforward, but achieving proper JIT inventory management is a far more complicated process.

The following are the foundations of JIT inventory management:

- Assess

Determine the employees, equipment, resources, and other assets required for your inventory management, purchase order management, and procurement procedures.

- Manage

Learn about your present inventory management methods from the ground up. As you deploy JIT processes, identify particular sections that need to be enhanced, deleted, or redone.

- Get buy-in

As you correctly present this “new method” to your team, consider your approach to change management.

- Connect

JIT’s inventory management relies on strong partnerships with dependable suppliers. This necessitates locating the best providers for your requirements and establishing their expectations for your future needs.

- Build

Although your staff will participate in the early stages of JIT implementation, they will also require formal training in these new processes. While many JIT training classes are available, you should adapt your sessions to your individual needs.

- Refine

Always look for ways to increase productivity at every step of the process.

What Benefits Does Just-In-Time Inventory Management Offer?

Given below are some of the benefits offered by the Just-In-Time Inventory Management strategy:

Lower Warehouse Storage Expenses

Inventory management may be expensive and becomes more costly as inventory levels increase.

There is also the expense of stocking, transferring, and managing goods over time, in addition to the cost of storage space.

You may reduce these expenses by using a leaner inventory management approach. While there are other ways to reduce inventory management expenses, adopting a just-in-time strategy will reduce your expenditures directly linked to inventory storage.

Decreased Total Inventory Costs

Buying inventory simply as needed implies you’re not tying up valuable capital in surplus stock.

Improved Cash Flow

You’ll have more cash to invest in your business if you spend less on supplies and inventory management.

The money you save may be better allocated into growth-related business activities, whether you utilise it to optimise JIT-related operations or invest it in other areas of the organisation.

Less Inventory Spoilage

Because most of the inventory you’ll be storing is already earmarked for use, there’s a considerably lesser risk of waste if you run a firm that stores things that can go bad, become obsolete, or depreciate if not sold within a specific timeframe.

While spoiling can still occur due to cancelled orders, human error, and other circumstances, JIT inventory management can assist in reducing the majority of time-based spoilage.

Less Dead Stock

Even though unsold inventory does not “technically” expire, demand for such things will surely wane.

If you have more stock than you can sell, you’ll have to choose a decision:

- Please keep the expectation that demand will rise again.

- It should be sold at a loss.

- Remove it entirely.

Unfortunately, many businesses wind up discarding unsold goods. A lean strategy alleviates this issue. The entire goal of JIT is to ensure that materials and products are “live” from when they are ordered from the supplier until they are delivered to the client.

Improved Product Quality

Though we haven’t discussed how JIT benefits the consumer, we must address its influence on product quality.

Because all items provided through JIT procedures are manufactured to order in some form, they are virtually always of more outstanding quality than their mass-produced equivalents.

More effective inventory management methods also reduce the likelihood of accidental damage, ensuring that each product is supplied to the client exactly as planned.

Potential drawbacks of JIT

As advantageous as a just-in-time approach to inventory management might be, several limitations exist.

Susceptibility to Supply Chain Disruptions

The epidemic has demonstrated how vulnerable the global supply chain may be.

Unfortunately, the outage severely impacted firms that operate on a just-in-time basis.

Even during “normal” times, the slightest disruption in the supply chain might disrupt your JIT procedures. The margin of error then reduces drastically to ensure that everything functions without a hitch for you to achieve your goals.

Vulnerability to Local Sourcing Costs

The trade-off is frequently monetary. Unless your suppliers can get their products locally, you’ll almost certainly pay a more fantastic price than you would from a well-known worldwide provider.

Higher Levels of Supplier Dependence

Considering the precedent, it should be evident that executing JIT inventory management entails relying on your suppliers.

An untrustworthy provider might cause significant issues. And, as previously stated, your most dependable selections will undoubtedly be among your most expensive.

In any event, you’ll need to become even more committed to your search for the proper suppliers for your company and your efforts to retain your connections with those suppliers over time.

More Exposure to Forecasting Errors

Many teams unknowingly jeopardise the “made-to-order” part of JIT inventory management to capitalise on current trends and other possibilities.

If evidence indicates that a given trend will likely continue long into the future, you may consider buying in larger quantities to manage the more impending demands.

However, there is always the possibility that your demand projections need to be corrected, leaving you with the same overstock issues you started with.

When Should a Business Transition to JIT?

A business should transition to JIT if the following align:

- If the products are produced and supplied quickly without delays.

- If the demand forecasts are accurate

- If the supply chain is equipped to absorb disruptions

- If the works and vendors are reliable

- If your workforce is aware of the JIT technique and is willing to implement it.

- If you have all the intended tools needed, such as software which facilitates inventory management, supplier relationship management and customer management

Which Are the Industries That Use JIT?

Some of the following industries use JIT:

- Automotive

- Manufacturing

- Construction

- Retail

Frequently Asked Questions about JIT

Q) What is the purpose of just-in-time inventory management?

A) JIT inventory management’s primary goal is to keep all inventory management-related expenditures to a minimum. While implementing JIT can benefit your company, the primary focus is building feasible inventory management procedures and practices.

Q) How does just in time improve efficiency?

A) JIT inventory management enhances efficiency by decreasing unnecessary inventory storage and, as a result, unnecessary processes.

As a result, your warehouse crew will be able to focus more on duties that genuinely support your company objectives.

Q) What’s the difference between JIT inventory management and JIT manufacturing?

A) JIT inventory management and JIT production are not the same, even if they both follow the lean philosophy.

JIT inventory management focuses on transporting and storing materials and goods before delivery. In contrast, JIT manufacturing focuses on the production process to ensure the development team has everything they need to build the product.

Proper inventory management is essential to simplify manufacturing, and efficient production is required to deliver orders on time.

Conclusion

In conclusion, businesses have to ensure that they have open lines of communication with their providers to guarantee the prompt distribution of materials and prevent stockouts. Companies could free up resources that would have been locked down in inventory-keeping costs if they did not keep inventory levels at optimum and reduce surplus inventory levels. By emphasising quality control and ongoing enhancement, just-in-time manufacturing can also assist in lowering wastage and raising overall productivity.